Just picture a whisky master blending a fine single malt. Now imagine that master distiller is no longer a person, but a technological advancement. That’s right, technology has found a home in whisky production and is making waves in the industry. Think of a distillery where the age-old copper stills are watched over by smart sensors. Or even a process where the art of maturation is played out in a virtual world. It’s not a scene from a futuristic movie, this is the reality for many distilleries today. But what does this marriage of old tradition and new tech mean for the future of whisky?

The role of technology in whisky production has moved beyond just being a novelty. It’s now a key player, taking on roles that were previously the domain of humans. This blend of the old and the new isn’t just something interesting to think about, it’s actually changing the face of the whisky industry. But what does it really mean for this centuries-old craft?

Technology’s role in the whisky industry is a topic that’s worth delving into. It’s not just about new ways to produce whisky, but about the future of the industry itself. Let’s take a closer look.

Embracing Automation in Whisky Production

As we delve into the world of whisky production, it’s clear that technology is playing a significant role in changing how we operate. From distillation to bottling, every step is being transformed, leading to improved efficiency and reduced need for manual labor. As we start to accept automation in whisky production, we’re starting to see its benefits in streamlining the manufacturing process. It’s not just about lessening physical effort but also about maintaining consistency and quality in every bottle.

For instance, smart sensors and devices connected to the internet are being used to monitor the process in real-time, making adjustments as needed to ensure the desired outcome. In addition, virtual reality simulations allow us to test aging processes and flavour profiles, opening up opportunities for innovation.

Artificial intelligence is contributing significantly, too. It’s helping us improve whisky blending and recipe development, resulting in unique and high-quality products. But the most important aspect of automation in whisky production is making the industry more sustainable. It’s reducing waste, saving energy, and ultimately cutting costs.

In this dynamic landscape, we’re not just producing whisky – we’re shaping the future of this beloved spirit. As we continue using technology, we are moulding an industry where producers and consumers benefit.

Innovations in the Whisky Aging Process

As we delve into the captivating world of whisky aging process innovations, we see how modern technology is challenging traditional practices and pioneering fresh approaches. New entrants, like Endless West, are dabbling in molecular whiskey creation, which indicates a bright future for the sector.

But it’s not just about molecular production. Here are some other interesting developments we’re witnessing:

- Bespoken Spirits are using microstates in their maturation process, which cuts down wood used by a whopping 97%.

- Cleveland Whiskey is tweaking pressure variations in stainless-steel tanks to diversify flavours.

- The industry sees a peaceful mix of age-old and modern methods, enriching the whisky world.

- Cutting-edge technology, like automation, is propelling whisky production to unprecedented levels.

- Joint ventures, such as the Advanced Forming Research Centre’s industry demonstrator, targeting cost-effective and uniform production.

These ground-breaking changes in the whisky aging process are not just pushing the envelope but also redefining whisky production. These changes foster a sense of community among us, bonded by our love for this timeless spirit and readiness to welcome the future. As we keep studying the influence of technology on whisky production, it’s clear that the field is brimming with thrilling opportunities.

Artificial Intelligence: The New Distiller

Stepping into the world of high-tech advancements, it’s fascinating to see how they’re making a key difference as the new-age whiskey maker, fine-tuning whiskey blending and recipe creation with an accuracy never seen before. This cutting-edge technology makes waves in Scotland’s whiskey industry, presenting answers to age-old challenges tied to space, barrel constraints, and initial investment needs.

This technology is honing the aging process and experimenting with flavour nuances, mimicking the aging process, and boosting the overall management and eco-friendliness of whiskey production. Its introduction into whiskey manufacturing signals an update and broadening within the spirits sector.

Here’s a quick rundown of the influence of this technology on whiskey manufacturing:

| New-Age Whiskey Maker | Influence | Result |

|---|---|---|

| Fine-tune blending & recipe | Heightened accuracy | Superior whiskey quality |

| Mimic aging & flavour trial | Bolstered management | Broadened flavour profiles |

| Solve age-old challenges | Heightened eco-friendliness | Updated Scotland’s whiskey industry |

As we dig deeper into the intersection of high-tech advancements and whiskey, we can see that this technology is reshaping how we understand and produce whiskey, hinting at a future where pinpoint accuracy, inventive practices, and sustainability are the standard.

The Role of Data Analytics in Whisky Making

Let’s discuss how data analytics plays a vital role in whisky making. It’s evident that through this approach, the production process has become more streamlined, leading to effective operations and cost reduction. The importance of data in the Scotch whisky industry has grown significantly, as it’s used to improve numerous aspects of whisky production.

Here’s how data analytics contributes to different areas of whisky production:

- Anticipating consumer tastes and market shifts: This helps create products that cater to consumers’ evolving tastes and keep up with market demand.

- Examining data on the aging process: This gives valuable insights into flavour development and maturation status, contributing to the overall quality of the whisky.

- Improving inventory management through data: Data analytics simplifies inventory and supply chain management, making operations run more smoothly and efficiently.

- Encouraging sustainable practices: Data analytics can pinpoint areas for improvement regarding environmental impact, resulting in greener whisky production methods.

In today’s technologically driven world, it’s important to realize that data analytics isn’t solely about technology. It’s also about uniting people around a common love for the skilled craft of whisky making.

Sustainability and Technology in Whisky Production

In the world of whisky production, we’re seeing a cool trend where technology and green practices are joining forces. Distilleries are becoming more earth-friendly by using clever tech solutions without compromising the quality of their spirits.

Data analytics play a big part in this. But it’s not just about numbers and spreadsheets. It’s about using that data to make smarter choices on how to run a distillery. This could be anything from how the distillery uses energy, disposes of waste or recycles water. All these efforts are helping to reduce the environmental impact of whisky production.

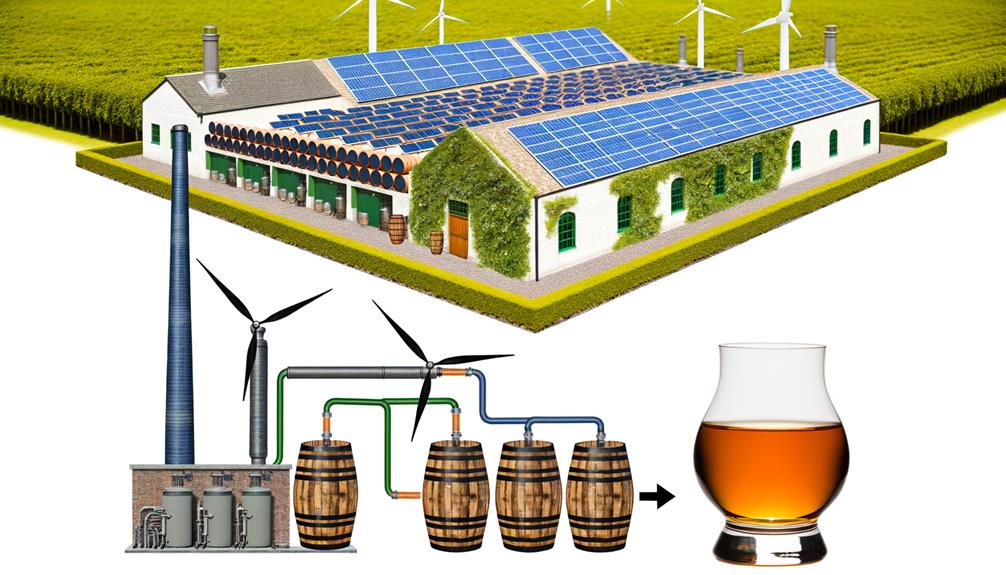

One of the really interesting ways technology is making whisky production greener is through renewable energy. Distilleries are starting to use solar and wind power, which is great for the environment. Plus, they’re finding innovative ways to turn waste into biofuel. This helps reduce reliance on fossil fuels and offers a clever solution to manage waste.

Water is another vital ingredient in whisky. How it’s managed can make a big difference to the environment. That’s where technology comes in with advanced filtration systems that recycle water, significantly reducing waste.

Frequently Asked Questions

What Is the Future of the Whiskey Industry?

When I think about what’s in store for the world of whiskey, I see a fascinating mix of old and new. The time-honoured practice of aging whiskey in barrels isn’t going anywhere, but it will be complemented by some exciting new methods that are just starting to make their mark. These new techniques have the potential to bring even more variety to the rich array of flavours we’ve come to love.

What Is the Outlook for the Whiskey Industry?

I’ve got this feeling that the whisky industry is really on the rise. You’ve got that old-school craftmanship still going strong, but at the same time, e all these new-fangled techniqueare s popping up. The result? There is a whole array of flavours to try out and a growing worldwide market. For those of us who love a good whisky, it’s a good time to be alive.

What Is a Still Used to Manufacture Whiskey?

You know, making whiskey is a pretty fascinating process, and it all starts with a still. This handy gadget heats our fermented liquid into a steamy vapour. As this vapour ascends, it splits apart and cools down, returning to a liquid form. But here’s the kicker – now it’s got alcohol in it! The shape and style of the still can even tweak the taste of the whiskey. So, the design of the still isn’t just about function; it’s also about the subtleties of flavour. Pretty cool, right?

How Is Whiskey Artificially Aged?

So, you’re curious about how whiskey gets its distinct flavour and character with the help of artificial aging? Well, it’s quite an intriguing process. It’s all about employing fresh, forward-thinking methods such as precision control and pressure-driven operations.

These methods, rather crafty if you ask me, use various types of wood in smaller amounts or even concocted lab-made flavour compounds. The aim is to recreate the effects of the age-old traditional aging process. It’s fascinating, isn’t it? How can modern techniques replicate the patience and time that usually go into making fine whiskey?